|

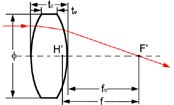

Double Convex Lens

| Double Convex Lens (aslo named Bi-Convex Lens) is most

suitable where the object and image are on opposite sides of the

lens and the ratio of the image and object (conjugate ratio)

distances is between 0.2 to 5. It is used in beam expanders,.

projection optics systems, optical viewers, imaging optics systems, optical character readers etc

... |

General Specifications |

Parameter |

Commercial Grade |

Substrate Material |

BK7 grade A optical glass, Fused Silica,

Sapphire etc. |

Diameter Tolerance |

+0/-0.15mm |

| Design Wavelength |

546.1nm |

Focal Length Tolerance |

+/-2%@546.1nm |

Clear Aperture |

>Central 85% of diameter |

Surface Quality |

60-40 S/D |

Centration |

<3 arc minutes |

Surface Accuracy |

¦Ë/4@632.8nm |

Chamfer |

0.25mm x 45¡ã |

Coating |

Uncoated |

BK7 Double Convex Lens Standard Products:

Part No. |

f(mm) |

¦Õ(mm) |

R1=R2(mm) |

tc (mm) |

te (mm) |

fb (mm) |

|

8.0 |

6.0 |

7.700 |

3.2 |

2.0 |

6.9 |

LDX0105 |

10.0 |

10.0 |

9.450 |

4.9 |

2.0 |

8.2 |

LDX0201 |

15.0 |

12.7 |

14.660 |

4.9 |

2.0 |

13.3 |

LDX0202 |

20.0 |

12.7 |

20.010 |

4.0 |

2.0 |

18.6 |

LDX0203 |

25.0 |

12.7 |

25.280 |

3.6 |

2.0 |

23.8 |

LDX0204 |

30.0 |

12.7 |

30.520 |

3.3 |

2.0 |

28.9 |

LDX0205 |

40.0 |

12.7 |

40.95 |

3.0 |

2.0 |

39.0 |

LDX0206 |

50.0 |

12.7 |

51.35 |

2.8 |

2.0 |

49.1 |

LDX0207 |

75.0 |

12.7 |

77.30 |

2.6 |

2.0 |

74.1 |

LDX0208 |

100.0 |

12.7 |

103.25 |

2.4 |

2.0 |

99.2 |

LDX0209 |

25.4 |

20.0 |

25.265 |

6.1 |

2.0 |

23.3 |

LDX0301 |

40.0 |

22.4 |

40.57 |

5.1 |

1.9 |

38.3 |

LDX0302 |

25.4 |

25.4 |

24.712 |

9.0 |

2.0 |

22.2 |

LDX0303 |

31.7 |

25.4 |

31.560 |

7.3 |

2.0 |

29.2 |

LDX0304 |

35.0 |

25.4 |

35.09 |

6.8 |

2.0 |

32.7 |

LDX0305 |

50.0 |

25.4 |

50.92 |

5.2 |

2.0 |

48.3 |

LDX0306 |

75.0 |

25.4 |

77.04 |

4.1 |

2.0 |

73.6 |

LDX0307 |

100.0 |

25.4 |

103.05 |

3.6 |

2.0 |

98.8 |

LDX0308 |

125.0 |

25.4 |

129.02 |

3.3 |

2.0 |

123.9 |

LDX0309 |

150.0 |

25.4 |

154.97 |

3.0 |

2.0 |

149.0 |

LDX0310 |

175.0 |

25.4 |

180.91 |

2.9 |

2.0 |

174.0 |

LDX0311 |

200.0 |

25.4 |

206.84 |

2.8 |

2.0 |

199.0 |

LDX0312 |

250.0 |

25.4 |

258.70 |

2.6 |

2.0 |

249.1 |

LDX0313 |

300.0 |

25.4 |

310.55 |

2.5 |

2.0 |

299.2 |

LDX0314 |

500.0 |

25.4 |

517.91 |

2.3 |

2.0 |

499.2 |

LDX0315 |

1000.0 |

25.4 |

1036.23 |

2.2 |

2.0 |

999.3 |

LDX0316 |

50.0 |

30.0 |

50.731 |

6.5 |

2.0 |

47.8 |

LDX0317 |

500.0 |

30.0 |

518.306 |

2.4 |

2.0 |

499.2 |

LDX0401 |

110.0 |

35.0 |

113.31 |

4.7 |

2.0 |

108.4 |

LDX0402 |

50.0 |

38.0 |

49.97 |

10.5 |

3.0 |

46.4 |

LDX0403 |

100.0 |

38.0 |

102.52 |

6.5 |

3.0 |

97.8 |

LDX0404 |

150.0 |

38.0 |

154.57 |

5.4 |

3.0 |

148.2 |

LDX0405 |

200.0 |

38.0 |

206.51 |

4.8 |

3.0 |

198.4 |

LDX0406 |

350.0 |

38.0 |

362.13 |

4.0 |

3.0 |

348.7 |

LDX0407 |

500.0 |

38.0 |

517.67 |

3.7 |

3.0 |

498.8 |

LDX0408 |

700.0 |

38.0 |

725.02 |

3.5 |

3.0 |

698.8 |

LDX0409 |

45.0 |

38.1 |

44.836 |

10.4 |

2.0 |

41.4 |

LDX0410 |

50.8 |

38.1 |

51.063 |

9.3 |

1.9 |

47.6 |

LDX0411 |

63.5 |

40.0 |

64.38 |

8.3 |

1.9 |

60.7 |

LDX0501 |

100.0 |

50.0 |

102.06 |

9.2 |

3.0 |

96.9 |

LDX0502 |

150.0 |

50.0 |

154.27 |

7.1 |

3.0 |

147.6 |

LDX0503 |

200.0 |

50.0 |

206.28 |

6.0 |

3.0 |

198.0 |

LDX0504 |

250.0 |

50.0 |

258.22 |

5.4 |

3.0 |

248.2 |

LDX0505 |

400.0 |

50.0 |

413.87 |

4.5 |

3.0 |

398.5 |

LDX0506 |

450.0 |

50.0 |

465.73 |

4.3 |

3.0 |

448.6 |

LDX0507 |

500.0 |

50.0 |

517.58 |

4.2 |

3.0 |

498.6 |

LDX0508 |

600.0 |

50.0 |

621.28 |

4.0 |

3.0 |

598.7 |

LDX0509 |

800.0 |

50.0 |

828.64 |

3.8 |

3.0 |

798.7 |

LDX0801 |

500.0 |

80.0 |

517.678 |

6.1 |

2.0 |

498.0 |

LDX0901 |

250.0 |

100.0 |

257.0 |

13.7 |

3.9 |

245.4 |

Fused Silica Double Convex Lens Standard Products:

Part No. |

f(mm) |

¦Õ(mm) |

R1=R2(mm) |

tc (mm) |

te (mm) |

fb (mm) |

LDX1201 |

15.0 |

12.7 |

12.90 |

5.3 |

2.0 |

13.1 |

LDX1202 |

20.0 |

12.7 |

17.69 |

4.4 |

2.0 |

18.4 |

LDX1203 |

25.0 |

12.7 |

22.38 |

3.8 |

2.0 |

23.7 |

LDX1204 |

30.0 |

12.7 |

27.04 |

3.5 |

2.0 |

28.8 |

LDX1205 |

40.0 |

12.7 |

36.31 |

3.1 |

2.0 |

38.9 |

LDX1301 |

35.0 |

25.4 |

30.99 |

7.4 |

2.0 |

32.4 |

LDX1302 |

50.0 |

25.4 |

45.10 |

5.7 |

2.0 |

48.0 |

LDX1303 |

75.0 |

25.4 |

68.32 |

4.4 |

2.0 |

73.5 |

LDX1304 |

100.0 |

25.4 |

91.42 |

3.8 |

2.0 |

98.7 |

LDX1305 |

150.0 |

25.4 |

137.52 |

3.2 |

2.0 |

148.9 |

LDX1306 |

175.0 |

25.4 |

160.55 |

3.0 |

2.0 |

174.0 |

LDX1307 |

200.0 |

25.4 |

183.58 |

2.9 |

2.0 |

199.0 |

LDX1308 |

250.0 |

25.4 |

229.61 |

2.7 |

2.0 |

249.1 |

LDX1309 |

300.0 |

25.4 |

275.64 |

2.6 |

2.0 |

299.1 |

LDX1310 |

500.0 |

25.4 |

459.71 |

2.4 |

2.0 |

499.2 |

LDX1311 |

1000.0 |

25.4 |

919.82 |

2.2 |

2.0 |

999.2 |

LDX1401 |

50.0 |

38.0 |

44.10 |

11.6 |

3.0 |

45.9 |

LDX1402 |

100.0 |

38.0 |

90.90 |

7.0 |

3.0 |

97.6 |

LDX1403 |

150.0 |

38.0 |

137.13 |

5.7 |

3.0 |

148.0 |

LDX1404 |

200.0 |

38.0 |

183.13 |

5.0 |

3.0 |

198.3 |

LDX1405 |

350.0 |

38.0 |

321.41 |

4.1 |

3.0 |

348.6 |

LDX1406 |

500.0 |

38.0 |

459.48 |

3.8 |

3.0 |

498.7 |

Note: Other material Double Convex Lenses, Cutting Lenses, Square Lenses, Rectangle Lenses and Coatings are available upon requestment.

The general tolerance specifications above provide a guideline regarding manufacturing capabilities for optics ranging in size from Diameter 1-350mm. The manufacturing limits are not absolute; tighter tolerances may be possible. Part specific tolerances may vary depending on component size, shape, and/or material. |